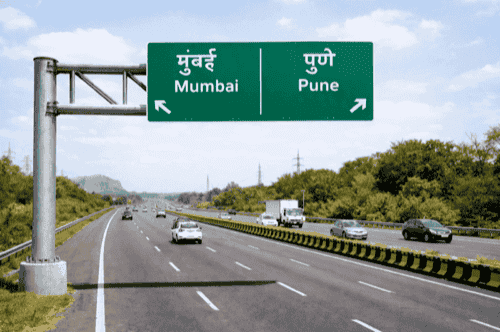

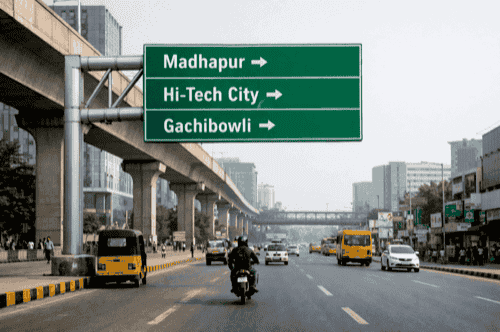

Cantilever Signage

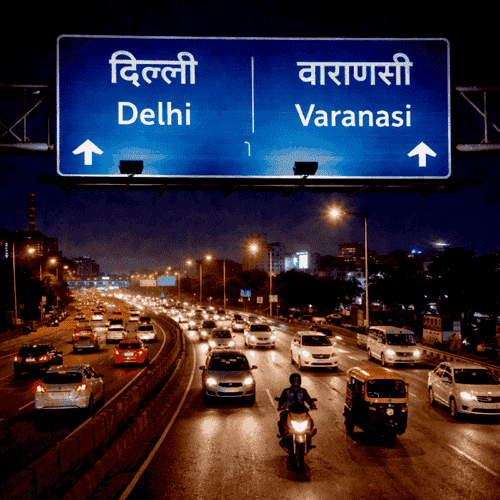

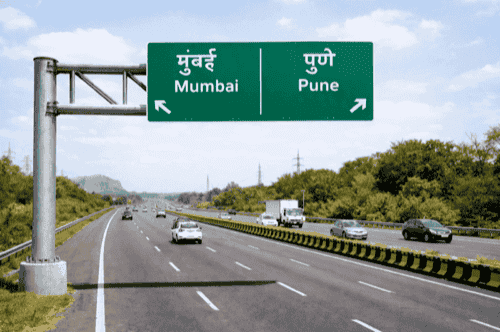

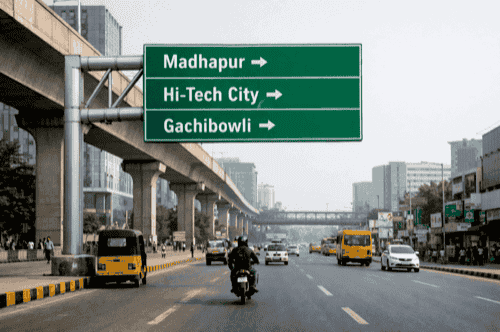

High-visibility cantilever signages manufactures for highways, expressways, and global road safety infrastructure.

Product Performance Metrics

Real-time statistics showcasing our product excellence

| Parameter | Specification |

|---|---|

| Product Type | Cantilever Signage Structure |

| Material | Structural Steel / Mild Steel |

| Finish | Hot Dip Galvanized / Painted |

| Sign Board | Retro-Reflective Sheeting |

| Mounting Type | Single-Pole Cantilever |

| Design Life | 15-20 Years |

| Application Area | High-Speed & Urban Road Networks |

| Compliance | IRC 67, MoRTH, ISO 9001:2015 |

Product Overview

YNM Safety is one of the trusted Cantilever signages manufacturers, delivering robust and high-visibility overhead signage solutions for highways, expressways, and major road corridors across global markets. Cantilever signages are designed to provide advance traffic information without obstructing road movement, ensuring maximum visibility and improved driver response. As YNM Safety manufactures premium-quality signages, our cantilever structures are engineered to withstand high wind loads, extreme weather conditions, and long-term outdoor exposure. These signages are widely used for lane guidance, directional information, exit identification, and regulatory traffic control. All cantilever signages are manufactured with strict quality control and comply with international road safety standards, making them suitable for government, EPC, and private infrastructure projects worldwide.

Detailed Specifications

Complete product information including dimensions, origin, and manufacturing details

Export Availability

Our Cantilever Signage is available and exported to 20+ worldwide

Asia

Europe

North America

South America

Africa

Oceania

Product Specification

Key features and product advantages of our Cantilever Signage

Key Features & Benefits

Application Areas

Where our Cantilever Signage provides maximum road safety and protection

Highways & Expressways

Cantilever signages provide clear overhead traffic guidance on highways and expressways.

Urban Roads & Streets

Cantilever signages are ideal for urban roads and busy city streets.

Toll Plazas

Cantilever signages are widely used at toll plazas for clear lane and regulatory guidance.

Industrial Roads

Cantilever signages support safe traffic movement on industrial roads.

Port & Logistics

Cantilever signages are suitable for ports and logistics hubs with heavy vehicle traffic.

Smart / Intelligent Transportation Systems (ITS)

Cantilever signages play a key role in smart and intelligent transportation systems.

Market Growth

Cantilever Signage Market Growth | YNM Safety

In 2023–24, the global portable cantilever sign systems market was valued at around USD 1.28 billion, showing growth from the previous year's baseline as demand expanded across infrastructure and commercial sectors. Analysts forecast that this segment will continue to grow at a steady CAGR of about 6.4%, lifting the market to roughly USD 2.22 billion by 2033. YNM Safety manufactures cantilever signages that support long-term performance and modern road safety requirements across various traffic environments.

Regional Market Share

Market Size Growth (in Billion USD)

Key Growth Factors of Cantilever Signage

Manufacturing Process of Cantilever Signage

As one of the leading Cantilever signages manufacturers, YNM Safety follows a precision-driven and quality-controlled production process to deliver durable, high-visibility signages for highway, road, and infrastructure projects worldwide. Below is the complete manufacturing workflow from raw material selection to final dispatch.

Raw Material Selection & Quality Inspection

The manufacturing process of cantilever signage begins with sourcing premium-grade raw materials to ensure structural strength and long service life. Materials include high-tensile structural steel, aluminum or GI sheets for signage panels, high-intensity reflective sheeting, industrial fasteners, and anti-corrosive coatings. Each batch undergoes strict quality inspection before production.

Steel Cutting & Structural Fabrication

Steel pipes, plates, and channels are precision-cut using CNC machines and hydraulic shearing systems. These components form the vertical support poles, horizontal cantilever arms, base plates, and stiffeners. Accurate fabrication ensures proper load distribution and stability for cantilever signages installed in high-wind and heavy-traffic areas.

Welding & Cantilever Frame Assembly

Cut steel components are assembled and welded using MIG and ARC welding techniques to create a rigid cantilever structure. All welded joints are checked for strength, alignment, and dimensional accuracy to meet safety and engineering standards followed by professional cantilever signages manufacturers.

Surface Preparation & Corrosion Protection

To enhance durability and weather resistance, the fabricated cantilever structure undergoes: Shot blasting or sand blasting to remove rust and impurities, application of anti-corrosive primer, and hot-dip galvanization or epoxy coating. This process ensures long-term protection against corrosion, moisture, and extreme environmental conditions.

Signage Panel Manufacturing

Signage panels are manufactured using aluminum or GI sheets and precisely cut to required dimensions. High-intensity reflective sheeting is applied for maximum visibility. Graphics, symbols, and text are added using digital printing, vinyl pasting, or screen printing, ensuring compliance with international signage standards.

Painting & Final Finishing

The cantilever structure is painted with weather-resistant, UV-protected industrial paints. This step enhances visual appeal, improves visibility, and extends the life of the signages in outdoor environments.

Final Assembly & Mounting

Manufactured signage panels are securely mounted onto the cantilever structure using heavy-duty bolts and fixtures. Electrical components are integrated where illuminated signages are required. All assemblies are tightened and rechecked for safety.

Quality Testing & Inspection

Every cantilever signage undergoes multiple quality checks, including: Dimensional accuracy, weld strength and finish, coating thickness, reflective performance and visual clarity. Load and wind-resistance inspections ensure the signages perform reliably in real-world conditions.

Packing & Labeling

Approved cantilever signage panels and structures are packed using protective materials to prevent transit damage. Each package is properly labeled with product details, project information, and handling instructions.

Storage & Dispatch

Once approved, the finished cantilever signages are carefully packed with protective materials to prevent transit damage. Each dispatch includes proper labeling, installation guidelines, and quality assurance documents, ensuring safe delivery to project locations worldwide.

Factory & Quality Proof

See our manufacturing facility and quality certifications that ensure premium product quality

Our Manufacturing Facility

State-of-the-art production facility ensuring consistent quality

Coming Soon

Factory images and facility tour will be available shortly

Quality Standards

Compliance with national and international road safety standards

ISO 9001:2015

Quality Management System Certification

IRC 67

Indian Roads Congress Standard for Road Signs