"Supplied 5000 RM of Thrie Beam Crash Barriers for highway safety infrastructure development project in Hyderabad. Our high-quality galvanized steel barriers provided excellent impact resistance and long-term durability for this critical road safety installation."

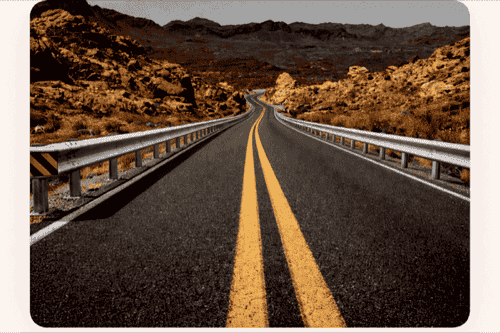

Thrie Beam Crash Barrier

High-strength thrie beam crash barriers manufacturers delivering superior impact resistance and road safety protection for highways, bridges, and infrastructure projects worldwide.

Product Performance Metrics

Real-time statistics showcasing our product excellence

| Parameter | Specification |

|---|---|

| Product Type | Thrie Beam Crash Barrier |

| Material Grade | High Strength Galvanized Steel |

| Thickness | As per IRC / MoRTH Specification |

| Coating | Hot Dip Galvanized |

| Impact Resistance | High Energy Absorption |

| Net Weight | 55 Kg/RM |

| Compliance | IRC 119, MoRTH 803, EN 1317 |

| Application Area | Highways, Bridges, Expressways |

Product Overview

YNM Safety is one of the leading thrie beam crash barriers manufacturers in India, delivering high-impact road safety solutions for highways, bridges, and expressways. As trusted metal beam crash barriers manufacturers and experienced barriers manufacturers, we design and produce crash barriers that offer superior strength and energy absorption during vehicle impact. Our thrie beam crash barriers provide enhanced protection compared to conventional W-beam systems, making them ideal for high-speed corridors and heavy vehicle routes. Being reputed ynm safety manufacturers, we ensure strict compliance with IRC 119, MoRTH 803, EN 1317, and ISO 9001:2015 standards. The thrie beam profile offers improved structural stability and better vehicle redirection, reducing accident severity and infrastructure damage.

Detailed Specifications

Complete product information including dimensions, origin, and manufacturing details

Export Availability

Our Thrie Beam Crash Barrier is available and exported to 20+ worldwide

Asia

Africa

Europe

North America

South America

Oceania

Product Specification

Key features and product advantages of our Thrie Beam Crash Barrier

Key Features & Benefits

Application Areas

Where our Thrie Beam Crash Barrier provides maximum road safety and protection

Highways & Expressways

Thrie beam crash barriers are widely installed on highways and expressways to improve road safety.

Urban Roads & Streets

Thrie beam barriers provide controlled vehicle containment in urban road networks.

Bridges & Flyovers

Thrie beam crash barriers ensure safety on bridges and elevated corridors.

Industrial Areas

Crash barriers protect industrial zones and logistics corridors.

Airports & Runways

Thrie beam barriers provide perimeter and safety protection in airports.

Coastal & Mountain Roads

Thrie beam crash barriers are ideal for coastal and hilly terrains.

Market Growth

Thrie Beam Crash Barrier Market Growth – Global Outlook

The global thrie beam crash barrier market has grown from around USD 1.5 billion in 2024 and is projected to reach nearly USD 2.5 billion by 2033. This reflects strong long-term growth driven by increasing investments in highway infrastructure, road modernization programs, and stricter road safety regulations worldwide.

Regional Market Share

Market Size Growth (in Billion USD)

Key Growth Factors of Thrie Beam Crash Barrier

Manufacturing Process of Thrie Beam Crash Barrier

YNM Safety is a leading Thrie Beam crash barrier manufacturer in India, delivering high-strength, precision-engineered road safety solutions. Our Thrie Beam metal crash barriers are manufactured using advanced roll forming technology and hot-dip galvanization to ensure maximum durability, corrosion resistance, and superior impact performance for highways and high-speed corridors.

Selection of High-Grade Steel Raw Material

The manufacturing process begins with procurement of premium quality hot rolled steel coils that comply with IS and ASTM standards. Each batch of steel is tested for tensile strength, yield strength, chemical composition, and surface quality. Using high-grade steel ensures structural integrity and long-term road safety performance.

Coil Slitting and Sheet Cutting

The steel coils are processed through automatic slitting machines to achieve the required width. The sheets are then cut to standard lengths as per Thrie Beam crash barrier specifications. This stage ensures uniform thickness and dimensional precision for consistent barrier performance.

Roll Forming into Thrie Beam Profile

The cut steel sheets pass through a multi-stage roll forming machine, where they are gradually shaped into the distinctive three-wave (Thrie Beam) profile. This process ensures accurate wave geometry, increased strength over W-beam barriers, improved vehicle containment, and high impact absorption capacity.

Precision Punching & Hole Making

After profiling, automated punching machines create precisely aligned holes for bolting joints, spacer systems, and post connections. Accurate punching ensures seamless installation and proper alignment during on-site assembly.

Deburring and Surface Preparation

Sharp edges and burrs are removed to ensure safe handling and smooth finishing. The beams are cleaned and prepared for galvanization to enhance corrosion resistance.

Hot-Dip Galvanization

To provide long-lasting protection against rust and environmental damage, the beams undergo hot-dip galvanization as per IS 4759 / ASTM A123 standards. The galvanizing process includes degreasing and pickling, flux treatment, and dipping in molten zinc. This creates a thick, uniform zinc coating that significantly increases the service life of the Thrie Beam metal crash barrier system.

Quality Control & Testing

Every batch undergoes strict quality inspection to ensure compliance with safety and infrastructure standards. Testing includes dimensional accuracy verification, zinc coating thickness test, impact resistance compliance, mechanical strength testing, and visual surface inspection. YNM Safety maintains high-quality standards to meet national highway project requirements.

Packing, Storage & Dispatch

Finished Thrie Beam crash barriers are bundled securely for safe transportation. Proper labeling and batch tracking ensure efficient dispatch to infrastructure projects across India. As a trusted Thrie Beam crash barrier manufacturer, YNM Safety ensures timely delivery for government, highway, bridge, and expressway projects.

Factory & Quality Proof

See our manufacturing facility and quality certifications that ensure premium product quality

Our Manufacturing Facility

State-of-the-art production facility ensuring consistent quality

Coming Soon

Factory images and facility tour will be available shortly

Quality Standards

Compliance with national and international road safety standards

MoRTH 803

Ministry of Road Transport & Highways Section 803 Specifications

ISO 9001:2015

Quality Management System Certification

EN 1317

European Standard for Road Restraint Systems

IRC 119

Indian Roads Congress Guidelines for Traffic Safety Barriers