Mandatory Sign Board (Octagonal)

High-visibility octagonal mandatory sign boards manufactured by YNM Safety, a trusted Sign Boards Manufacturer delivering durable and reflective safety signage solutions worldwide.

Product Performance Metrics

Real-time statistics showcasing our product excellence

| Parameter | Specification |

|---|---|

| Product Type | Mandatory Sign Board (Octagonal) |

| Shape | Octagonal |

| Base Material | ACP / Aluminium / GI Sheet |

| Reflective Grade | Engineer Grade / HIP / DG |

| Printing Type | UV Digital / Screen Printing |

| Mounting | Pole Mounted / Wall Mounted |

| Durability | 7-10 Years Outdoor |

| Compliance | MORTH & IRC 67 |

Product Overview

YNM Safety is one of the leading Mandatory Sign Board Manufacturers YNM Safety brand specializing in octagonal traffic and regulatory sign boards. As a professional Sign Boards Manufacturer, YNM Safety delivers high-visibility, weather-resistant, and long-lasting mandatory signage for highways, industrial zones, construction projects, and public infrastructure. Our octagonal mandatory sign boards are designed to ensure maximum visibility during day and night conditions. Being trusted YNM manufactures, we provide customized sizes, reflective grades, and project-based production solutions to meet government and infrastructure requirements.

Detailed Specifications

Complete product information including dimensions, origin, and manufacturing details

Export Availability

Our Mandatory Sign Board (Octagonal) is available and exported to 20+ worldwide

North America

Europe

Asia-Pacific

Middle East & Africa

South America

Product Specification

Key features and product advantages of our Mandatory Sign Board (Octagonal)

Key Features & Benefits

Application Areas

Where our Mandatory Sign Board (Octagonal) provides maximum road safety and protection

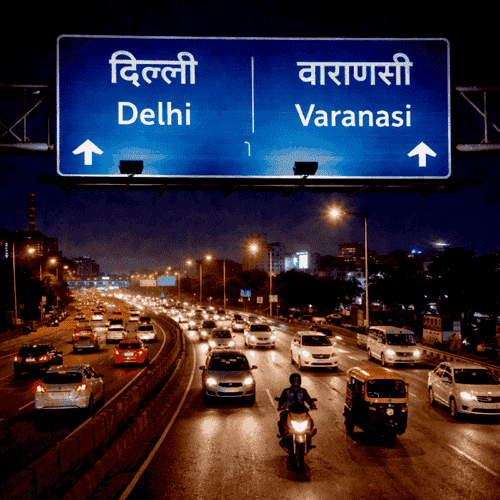

Road & Traffic Management

Octagonal mandatory sign boards ensure clear traffic control and regulatory compliance on highways and urban roads.

Industrial Facilities

Mandatory sign boards enforce safety instructions within industrial zones.

Construction Sites

Mandatory sign boards improve safety awareness at construction locations.

Commercial & Public Areas

Octagonal sign boards provide guidance and safety instructions in public spaces.

Educational Institutions

Mandatory sign boards improve safety and traffic regulation within campuses.

Residential & Gated Communities

Mandatory sign boards regulate traffic inside residential complexes.

Market Growth

Mandatory Sign Board (Octagonal) Market Growth | YNM Safety

The global mandatory sign board (octagonal) market continues to grow steadily as infrastructure development and safety awareness increase worldwide. Stronger workplace and road safety regulations are driving demand for high-quality sign boards. The market is projected to grow at a CAGR of approximately 4.5–5.8% over the coming years, supported by expanding road networks, smart city development, and industrial safety compliance.

Regional Market Share

Market Size Growth (in Billion USD)

Key Growth Factors of Mandatory Sign Board (Octagonal)

Manufacturing Process of Mandatory Sign Board (Octagonal)

YNM Safety manufactures octagonal mandatory sign boards through a controlled, quality-driven process to ensure high visibility, durability, and compliance with road safety standards.

Raw Material Selection

High-quality aluminium sheets (2mm–3mm thickness) are selected for durability and corrosion resistance. For long life, rust-proof materials are preferred as per IRC / MoRTH standards.

Cutting into Octagonal Shape

The aluminium sheet is cut into an accurate octagonal shape using CNC cutting or hydraulic shearing machines to ensure precise dimensions.

Edge Bending / Flanging

Edges are bent (usually 25mm border) using a bending machine to improve strength and avoid sharp edges.

Surface Cleaning & Pre-Treatment

The board surface is cleaned with chemicals to remove oil, dust, and impurities. This ensures better adhesion of reflective sheeting.

Application of Retro-Reflective Sheeting

High-intensity or engineering grade retro-reflective sheeting is pasted on the surface using roller lamination machines for strong bonding and night visibility.

Printing / Symbol Pasting

Mandatory symbols (as per traffic regulations) are printed using UV printing or screen-printing method. Standard colours like red, white, and black are used.

Curing & Drying

The board is kept for proper curing to ensure ink bonding and long-lasting finish.

Back Support & Mounting Clamp Fixing

GI clamps or MS brackets are fixed at the backside for pole mounting.

Quality Inspection

Each sign board is inspected for reflectivity, size accuracy, colour standards, and adhesion strength.

Packing & Dispatch

Boards are packed carefully with protective covering to avoid scratches during transportation.

Factory & Quality Proof

See our manufacturing facility and quality certifications that ensure premium product quality

Our Manufacturing Facility

State-of-the-art production facility ensuring consistent quality

Coming Soon

Factory images and facility tour will be available shortly

Quality Standards

Compliance with national and international road safety standards

ISO 9001:2015

Quality Management System Certification

MORTH

Ministry of Road Transport & Highways Specifications

IRC 67

Indian Roads Congress Standard for Road Signs