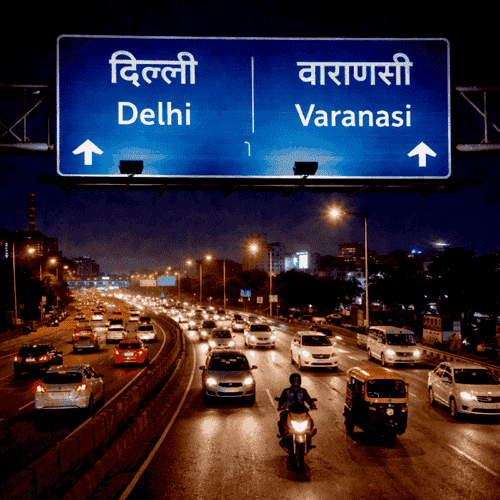

Retro Reflective Gantry Signage

High-visibility retro reflective gantry signage manufacturers for highways, expressways & advanced traffic guidance systems.

Product Performance Metrics

Real-time statistics showcasing our product excellence

| Parameter | Specification |

|---|---|

| Product Type | Retro Reflective Gantry Signage |

| Sign Type | Overhead / Cantilever / Portal Gantry |

| Reflective Sheeting | Engineer Grade / High Intensity / Diamond Grade |

| Base Material | Aluminium Sheet |

| Visibility Range | Long-distance visibility |

| Mounting | Gantry Structure |

| Application Area | Highways & Expressways |

| Compliance | MoRTH, IRC, IS Standards |

Product Overview

YNM Safety is one of the trusted retro reflective gantry signage manufacturers, offering premium-quality overhead signboard solutions for modern road infrastructure. We manufacture retro reflective gantry signages designed for long-distance visibility, lane guidance, and effective traffic communication on highways, expressways, flyovers, and major junctions. Our retro reflective gantry signboards are manufactured using high-grade aluminium sheets, certified retro reflective sheeting, and robust gantry structures. YNM Safety manufactures gantry signages that provide excellent day and night visibility, weather resistance, and long service life. As experienced gantry signage manufacturers, YNM Safety follows strict quality control processes and manufactures products compliant with MoRTH, IRC, IS, and ASTM standards for national and international road safety projects.

Detailed Specifications

Complete product information including dimensions, origin, and manufacturing details

Export Availability

Our Retro Reflective Gantry Signage is available and exported to 20+ worldwide

North America

Europe

Asia-Pacific

Middle East & Africa

South America

Product Specification

Key features and product advantages of our Retro Reflective Gantry Signage

Key Features & Benefits

Application Areas

Where our Retro Reflective Gantry Signage provides maximum road safety and protection

Highways & Expressways

Retro reflective gantry signages provide clear overhead guidance on highways and expressways.

Urban Roads & City Streets

Gantry signages support organized traffic movement on urban roads and city streets.

Toll Plazas & Bridges

Gantry signages improve lane identification at toll plazas and bridge approaches.

Airports & Railway Stations

Gantry signages provide effective traffic guidance in transport hubs.

Industrial Sites & Ports

Gantry signages ensure controlled traffic movement in industrial areas.

Commercial & Advertising

Gantry structures support commercial signage and advertising displays.

Smart / Intelligent Transportation Systems (ITS)

Gantry signages integrate seamlessly with smart traffic systems.

Market Growth

Retro Reflective Gantry Signage Market Growth | YNM Safety

The global gantry signage market is experiencing steady growth, valued at around USD 2–3 billion in 2024 and expected to grow at a 5–7% CAGR through 2030. Growth is driven by infrastructure expansion, smart city initiatives, and adoption of digital/LED signage. YNM Safety manufactures retro reflective gantry signages that support long-term performance and modern road safety requirements across various traffic environments.

Regional Market Share

Market Size Growth (in Billion USD)

Key Growth Factors of Retro Reflective Gantry Signage

Manufacturing Process of Retro Reflective Gantry Signage

YNM Safety manufactures retro reflective gantry signages through a controlled, quality-driven process to ensure high visibility, structural strength, durability, and compliance with national and international road safety standards.

Raw Material Procurement & Inspection

High-quality raw materials such as aluminium sheets, retro reflective sheeting, structural steel sections, fasteners, and protective coatings are sourced from certified suppliers. Each material is inspected to meet required quality, thickness, and performance standards before manufacturing.

Aluminium Sheet Cutting & Panel Preparation

Aluminium sheets are accurately cut to required gantry signage dimensions using precision cutting machines. Proper panel preparation ensures uniform size, smooth edges, and structural stability for overhead signboards.

Surface Cleaning & Pre-Treatment

The aluminium panels undergo surface cleaning and chemical pre-treatment to remove oil, dust, and impurities. This step improves adhesion of retro reflective sheeting and enhances long-term durability.

Application of Retro Reflective Sheeting

Certified retro reflective sheeting (Engineer Grade, High Intensity, or Diamond Grade) is carefully applied to the prepared aluminium panels. Controlled application ensures wrinkle-free bonding, uniform reflectivity, and long-distance visibility.

Graphic Printing & Message Overlay

Traffic symbols, route information, and directional text are applied using high-quality digital printing or cut vinyl overlays. UV-resistant inks and protective overlays ensure clear readability and color stability in all weather conditions.

Gantry Structure Fabrication

Structural steel sections for gantry frames are fabricated, welded, and assembled as per approved engineering drawings. YNM Safety manufactures gantry structures with high load-bearing capacity to support large overhead signboards safely.

Quality Testing & Reflectivity Inspection

Finished gantry signages undergo strict quality checks, including reflectivity testing, adhesion strength, dimensional accuracy, and structural inspection. All products are tested to comply with MoRTH, IRC, IS, and ASTM standards.

Packing & Labeling

Approved gantry signage panels and structures are packed using protective materials to prevent transit damage. Each package is properly labeled with product details, project information, and handling instructions.

Storage & Dispatch

The finished retro reflective gantry signages are stored in a clean and secure facility before dispatch. Products are dispatched with proper documentation to ensure safe delivery to project sites across India and global markets.

Factory & Quality Proof

See our manufacturing facility and quality certifications that ensure premium product quality

Our Manufacturing Facility

State-of-the-art production facility ensuring consistent quality

Coming Soon

Factory images and facility tour will be available shortly

Quality Standards

Compliance with national and international road safety standards

ISO 9001:2015

Quality Management System Certification

IRC 67

Indian Roads Congress Standard for Road Signs

MoRTH

Ministry of Road Transport & Highways Specifications