"Supplied 85 units of Impact Attenuators for highway safety infrastructure upgrade project in Maharashtra. Our high-quality attenuator systems provided excellent impact absorption and protection at critical highway points."

Attenuator

High-performance impact attenuator manufactured by YNM Safety, a trusted Attenuator manufacture delivering advanced metal beam crash barrier safety systems for global highway infrastructure.

Product Performance Metrics

Real-time statistics showcasing our product excellence

| Parameter | Specification |

|---|---|

| Product Type | Road Safety Impact Attenuator |

| Material | High Strength Steel |

| System Compatibility | Metal Beam Crash Barrier |

| Design Speed Variants | 80 kmph / 100 kmph / 110 kmph |

| Installation | Bolt & Anchor Based |

| Corrosion Protection | Galvanized Steel |

| Compliance | IRC SP 99:2013 & MoRTH |

| Application Area | Highways, Toll Plazas, Bridge Approaches |

Product Overview

YNM Safety is a leading Attenuator manufacturer in India specializing in high-performance impact attenuation systems designed to reduce collision severity and protect motorists. Our Attenuator YNM manufactured systems are engineered as energy-absorbing safety devices that work seamlessly with metal beam crash barrier installations. These systems are tested and compliant with IRC SP 99:2013 and MoRTH guidelines, ensuring reliable performance in high-speed highway environments. As a reputed YNM Safety manufacturer of road safety systems, we deliver durable, corrosion-resistant, and structurally strong attenuators suitable for national highways, expressways, urban corridors, and infrastructure projects worldwide.

Detailed Specifications

Complete product information including dimensions, origin, and manufacturing details

Export Availability

Our Attenuator is available and exported to 20+ worldwide

Asia

North America

Europe

Africa

Middle East

South America

Product Specification

Key features and product advantages of our Attenuator

Key Features & Benefits

Application Areas

Where our Attenuator provides maximum road safety and protection

Highway Exits and Entrances

Attenuator systems protect motorists at highway entry and exit points.

Toll Plazas

Designed to safeguard toll booths and vehicle lanes.

Bridge Approaches

Critical protection for bridge ends and approach zones.

Work Zones and Construction Areas

Ensures safety in temporary traffic management zones.

Sharp Curves on Roads

Installed at dangerous curved sections.

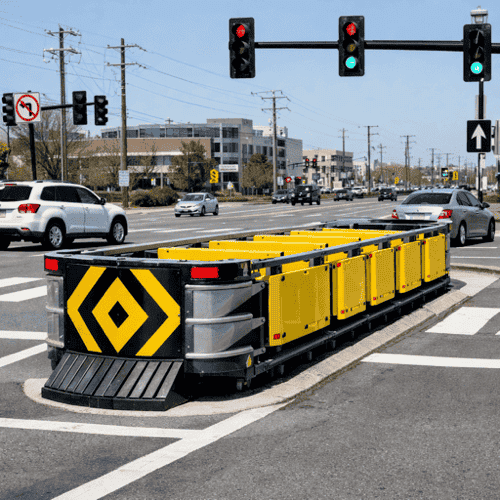

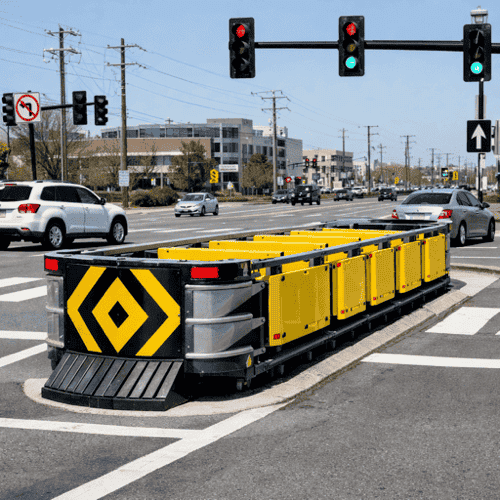

Intersections and Junctions

Provides impact protection at busy road intersections.

Market Growth

Attenuator Barrier Market Growth – Global Outlook

The global attenuator barrier market has grown steadily in recent years, reaching approximately USD 2.0 billion by 2024. Growth has been driven by stricter road safety regulations and expanding highway infrastructure. Looking ahead, the market is expected to grow at a CAGR of 4–5% through 2030, supported by increasing government investments in transportation and advanced barrier technologies.

Regional Market Share

Market Size Growth (in Billion USD)

Key Growth Factors of Attenuator

Manufacturing Process of Attenuator

YNM Safety is a leading Attenuator manufacturer in India, delivering high-performance impact attenuation systems designed to reduce collision severity and protect motorists. Our attenuators are manufactured using advanced engineering processes and high-strength galvanized steel to ensure maximum durability, corrosion resistance, and superior impact absorption performance for highways, toll plazas, and bridge approaches.

Design Engineering & Material Selection

The manufacturing process begins with precision design engineering based on IRC SP 99:2013 and MoRTH specifications. High-strength steel is selected and tested for tensile strength, yield strength, and chemical composition to ensure structural integrity and optimal energy absorption performance.

Steel Cutting & Component Fabrication

Steel sheets and structural components are precision-cut using advanced CNC machines to achieve exact dimensions. Each component is fabricated to meet the specific design speed requirements (80/100/110 kmph) ensuring consistent quality across all attenuator units.

Profile Forming & Shaping

The cut steel components are processed through forming machines to achieve the required energy-absorbing profiles. This critical stage ensures the attenuator can effectively absorb and dissipate collision energy during impact events.

Welding & Assembly

Components are precisely welded and assembled following strict quality control procedures. All welds are inspected for structural integrity to ensure the attenuator system performs reliably under high-impact conditions.

Surface Preparation & Cleaning

Assembled attenuator units undergo thorough surface preparation including degreasing and cleaning to remove oils, rust, and impurities. This ensures optimal adhesion during the galvanization process.

Hot-Dip Galvanization

To provide long-lasting corrosion protection, the attenuator units undergo hot-dip galvanization as per IS 4759 / ASTM A123 standards. This creates a uniform zinc coating that significantly extends service life in harsh highway environments.

Quality Testing & Inspection

Every attenuator unit undergoes comprehensive quality testing including dimensional accuracy verification, coating thickness measurement, visual inspection, and compliance verification with IRC SP 99:2013 and MoRTH standards.

Packing, Documentation & Dispatch

Approved attenuator units are securely packed with proper labeling and documentation. Quality certificates are generated, and products are dispatched to project sites with installation guidelines and technical support.

Factory & Quality Proof

See our manufacturing facility and quality certifications that ensure premium product quality

Our Manufacturing Facility

State-of-the-art production facility ensuring consistent quality

Coming Soon

Factory images and facility tour will be available shortly

Quality Standards

Compliance with national and international road safety standards

MoRTH 803

Ministry of Road Transport & Highways Section 803 Specifications

ISO 9001:2015

Quality Management System Certification

EN 1317

European Standard for Road Restraint Systems

IRC 119

Indian Roads Congress Guidelines for Traffic Safety Barriers