Enamel Paint

Premium quality enamel paint manufacturers delivering durable, high-gloss, weather-resistant coatings for architectural, industrial, automotive, and protective applications worldwide.

Product Performance Metrics

Real-time statistics showcasing our product excellence

| Parameter | Specification |

|---|---|

| Product Type | Enamel Paint |

| Base Type | Synthetic / Alkyd Based |

| Finish | High Gloss / Semi Gloss |

| Application Method | Brush / Roller / Spray |

| Drying Time | Surface Dry – 6 to 8 Hours |

| Adhesion | Excellent on Metal & Wood |

| Weather Resistance | High UV & Moisture Resistance |

| Compliance | IS164:2023 |

Product Overview

YNM Safety is one of the leading enamel paint manufacturers in India, offering premium-quality enamel coatings designed for superior durability, gloss retention, and long-term surface protection. As trusted paints manufacturers and recognized ynm safety paints manufacturers, we provide enamel paint solutions for architectural, industrial, automotive, and protective coating applications. Our enamel paint is formulated with high-performance resins and pigments to deliver excellent adhesion on metal, wood, and previously painted surfaces. Being experienced enamel paint manufacturers, YNM Safety ensures smooth finish, resistance to corrosion, and long-lasting colour stability even under harsh environmental conditions. As reliable ynm safety manufacturers, we focus on advanced production technology, strict quality control, and compliance with IS164:2023 standards to serve domestic and global markets.

Detailed Specifications

Complete product information including dimensions, origin, and manufacturing details

Export Availability

Our Enamel Paint is available and exported to 20+ worldwide

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Product Specification

Key features and product advantages of our Enamel Paint

Key Features & Benefits

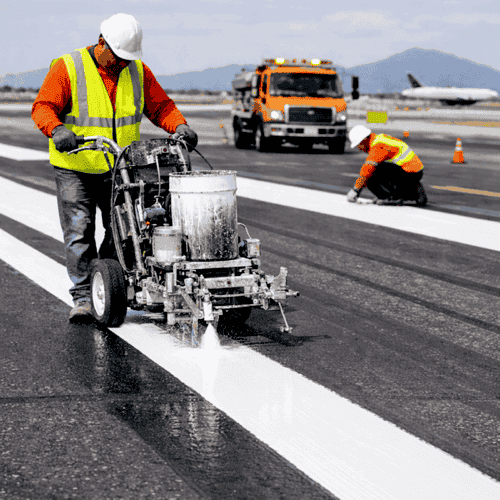

Application Areas

Where our Enamel Paint provides maximum road safety and protection

Architectural & Decorative Coatings

Enamel paint is widely used for decorative finishes in residential and commercial buildings.

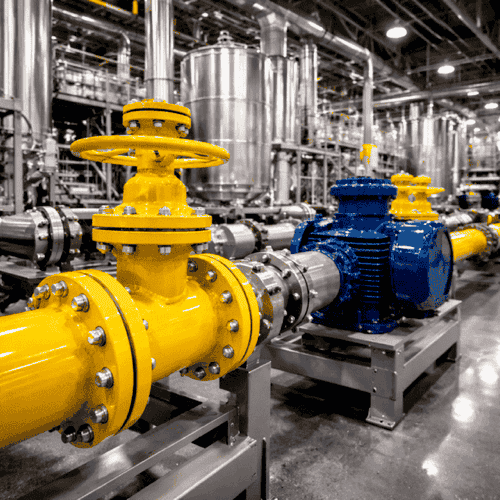

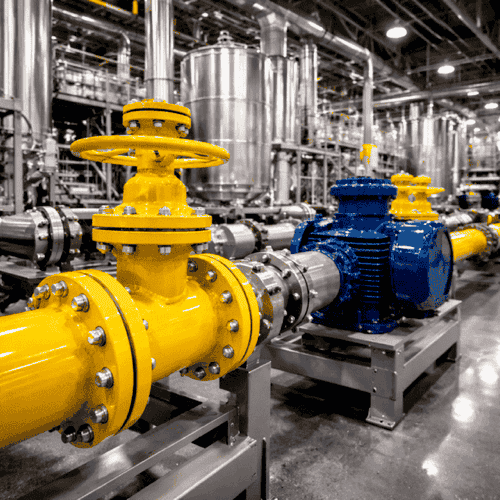

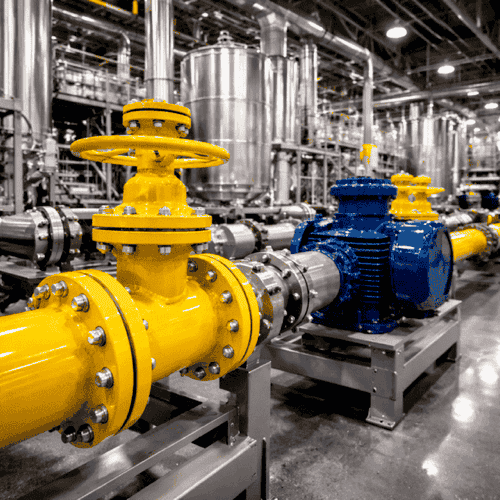

Industrial Coatings

Industrial enamel paint provides durable protection for machinery and equipment.

Automotive Coatings

Enamel paint is used in automotive refinishing and metal surface coating.

Wood Coatings

Enamel paint enhances the durability and finish of wooden surfaces.

Marine & Protective Coatings

Enamel paint is suitable for marine and protective coating applications.

Metal Fabrication

Enamel paint provides protective coating for fabricated metal components.

Market Growth

Enamel Paint Market Growth | YNM Safety

The global enamel paint market is experiencing steady growth driven by rising demand across construction, automotive, and industrial sectors. The enamel coatings market was estimated at approximately USD 6.23 billion in 2024. The global enamel product market is forecast to grow from about USD 4.49 billion in 2025 to USD 8.46 billion by 2032, registering a CAGR of approximately 9.46%.

Regional Market Share

Market Size Growth (in Billion USD)

Key Growth Factors of Enamel Paint

Manufacturing Process of Enamel Paint

As a leading enamel paint manufacturer, YNM Safety follows a systematic and quality-controlled production process to ensure superior gloss, durability, and long-lasting performance. Our enamel paints are manufactured as per IS 164:2023 standards, delivering excellent finish and protection for metal and wood surfaces.

Raw Material Selection & Quality Testing

The manufacturing process begins with the careful selection of high-quality raw materials such as alkyd resins, pigments, solvents, additives, and dryers. Each raw material undergoes strict laboratory testing to ensure it meets required performance parameters and industry standards.

Resin Preparation

Alkyd resin, the backbone of enamel paint, is prepared or sourced as per formulation requirements. The resin provides gloss, hardness, adhesion, and durability to the final product. Proper resin quality ensures excellent surface finish and weather resistance.

Pigment Dispersion (Grinding Process)

In this stage, pigments and extenders are mixed with a portion of resin and solvents. The mixture is transferred to high-speed dispersers or ball mills for grinding. This process ensures uniform colour development, proper particle size reduction, enhanced hiding power, and smooth finish.

Let-Down Process

After grinding, the pigment paste is transferred to mixing tanks where the remaining resin, solvents, and additives are added. This stage adjusts viscosity, gloss level, drying time, and flow and leveling properties. The formulation is carefully monitored to achieve the desired performance characteristics.

Filtration

The paint is passed through fine filters to remove impurities, oversized particles, or contaminants. This step ensures a smooth, lump-free finish and improves shelf stability.

Quality Control Testing

Before packaging, the enamel paint undergoes rigorous quality checks including viscosity test, gloss measurement, drying time test, adhesion test, flexibility test, shade matching, and coverage test. At YNM Safety, every batch is tested to maintain consistent quality and compliance with IS164:2023 standards.

Filling & Packaging

After approval from the quality control department, the paint is filled into containers using automated filling machines. Proper labeling, batch coding, and sealing are done to ensure safe storage and transportation.

Storage & Dispatch

Finished products are stored in controlled warehouse conditions before dispatch. With a production capacity of 50 KL per month and 600 KL annually, YNM Safety ensures timely delivery across India and exports to 20+ countries worldwide.

Factory & Quality Proof

See our manufacturing facility and quality certifications that ensure premium product quality

Our Manufacturing Facility

State-of-the-art production facility ensuring consistent quality

Coming Soon

Factory images and facility tour will be available shortly

Quality Standards

Compliance with national and international road safety standards

ISO 9001:2015

Quality Management System Certification

IS164:2023

Indian Standard for Enamel Paint