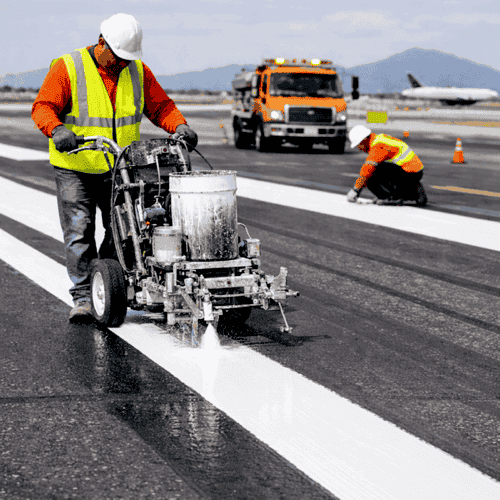

"Supplied hot thermoplastic road marking paint for highway road marking project. Our thermoplastic paints provided excellent durability and visibility for this major infrastructure project."

Hot Thermoplastic Road Marking Paint

YNM Safety - Leading hot thermoplastic road marking paint manufacturers providing high-performance thermoplastic paint for highways, expressways & urban road safety. ISO certified manufacturers.

Product Performance Metrics

Real-time statistics showcasing our product excellence

| Parameter | Specification |

|---|---|

| Product Type | Hot Thermoplastic Road Marking Paint |

| Application Method | Hot-applied |

| Softening Point | ≥ 102°C |

| Glass Beads Content | 20–30% |

| Available Colors | White / Yellow |

| Drying Time | 2–5 minutes |

| Application Surface | Asphalt & Concrete |

| Compliance | MoRTH, IRC, IS Standards |

Product Overview

YNM Safety is among the leading hot thermoplastic road marking paint manufacturers in India, delivering premium-quality hot thermoplastic paint designed for long-lasting and high-visibility road markings. We manufacture thermoplastic road marking paints widely used on highways, expressways, city roads, junctions, pedestrian crossings, and parking areas. YNM manufactures complete road safety solutions including hot thermoplastic paint, cold plastic paint, and metal beam crash barriers. Our hot thermoplastic paints are produced using high-grade resins, pigments, fillers, and reflective glass beads. YNM Safety manufactures thermoplastic road marking paint that ensures excellent adhesion, fast setting, and superior night-time reflectivity for optimal road safety performance. As one of the trusted hot thermoplastic paint manufacturers and exporters, YNM Safety follows strict quality control systems and manufactures products compliant with MoRTH, IRC, and IS standards for infrastructure and road safety projects. We export our hot thermoplastic paint and road safety products to 50+ countries worldwide.

Detailed Specifications

Complete product information including dimensions, origin, and manufacturing details

Export Availability

Our Hot Thermoplastic Road Marking Paint is available and exported to 40+ worldwide

North America

Europe

Asia-Pacific

Latin America

Middle East

Africa

Product Specification

Key features and product advantages of our Hot Thermoplastic Road Marking Paint

Key Features & Benefits

Application Areas

Where our Hot Thermoplastic Road Marking Paint provides maximum road safety and protection

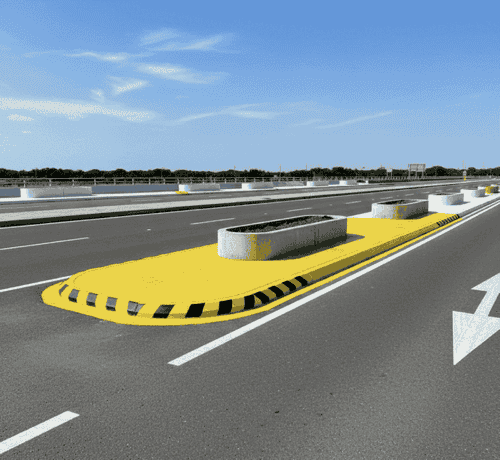

Highways & Expressways

YNM Hot Thermoplastic Paints deliver durable and high-visibility road markings for highways and expressways.

City Roads & Streets

YNM thermoplastic paints ensure clear and long-lasting markings for city roads and streets.

Pedestrian Crossings

YNM hot thermoplastic paints enhance visibility and safety at pedestrian crossings.

Parking Areas

YNM thermoplastic paints provide durable and organized parking area markings.

Industrial Roads & Runways

YNM thermoplastic paints deliver heavy-duty performance for industrial roads and runways.

Zebra Crossings & Junctions

YNM thermoplastic paints ensure bold and highly visible markings at junctions and zebra crossings.

Market Growth

Hot Thermoplastic Road Marking Paint Market Growth | YNM Safety

The hot thermoplastic road marking paint market is expanding due to growing investments in road infrastructure and traffic safety management. Contractors increasingly prefer thermoplastic paints for their durability and reflectivity. YNM Safety manufactures thermoplastic road marking paints that support long-term performance and modern road safety requirements across various traffic environments.

Regional Market Share

Market Size Growth (in Billion USD)

Key Growth Factors of Hot Thermoplastic Road Marking Paint

Manufacturing Process of Hot Thermoplastic Road Marking Paint

YNM Safety manufactures hot thermoplastic paints through a controlled, quality-driven process to ensure excellent durability, adhesion, reflectivity, and compliance with road safety standards.

Raw Material Procurement & Inspection

High-quality raw materials such as thermoplastic resin, pigments, fillers, glass beads, and additives are sourced from certified suppliers. Each batch is inspected and tested to meet required quality and performance standards.

Weighing & Batch Formulation

All raw materials are accurately weighed as per approved formulation to ensure consistent quality. Proper formulation is critical for durability, flow properties, and reflectivity of YNM hot thermoplastic paints.

High-Temperature Mixing

The measured materials are fed into high-temperature mixers where they are uniformly blended. Controlled heating ensures proper melting and bonding of resins, pigments, and fillers.

Homogeneous Compound Preparation

The molten mixture is processed until a uniform and lump-free compound is achieved. This step ensures smooth application, consistent color, and strong adhesion to road surfaces.

Cooling & Solidification

The hot thermoplastic compound is cooled under controlled conditions to solidify into stable material. Proper cooling prevents cracks, segregation, and quality variations.

Crushing & Granulation

The solidified material is crushed and granulated into uniform-sized thermoplastic paint granules. This form allows easy melting during on-site road marking application.

Quality Testing & Inspection

YNM Safety conducts rigorous quality tests including softening point, flow resistance, color stability, glass bead content, and adhesion performance to ensure compliance with standards.

Packaging & Labeling

Approved thermoplastic paint granules are packed in moisture-resistant bags with proper labeling. Packaging includes product name, batch number, manufacturing date, and application guidelines.

Storage & Dispatch

Finished products are stored in a clean and dry warehouse before dispatch. YNM thermoplastic paints are dispatched with proper documentation to ensure safe delivery to customers.

Factory & Quality Proof

See our manufacturing facility and quality certifications that ensure premium product quality

Our Manufacturing Facility

State-of-the-art production facility ensuring consistent quality

Coming Soon

Factory images and facility tour will be available shortly

Quality Standards

Compliance with national and international road safety standards

ISO 9001:2015

Quality Management System Certification

IS 164

Indian Standard for Road Marking Materials

MoRTH 803

Ministry of Road Transport & Highways Specifications

BS 3262

British Standard for Thermoplastic Road Marking Materials