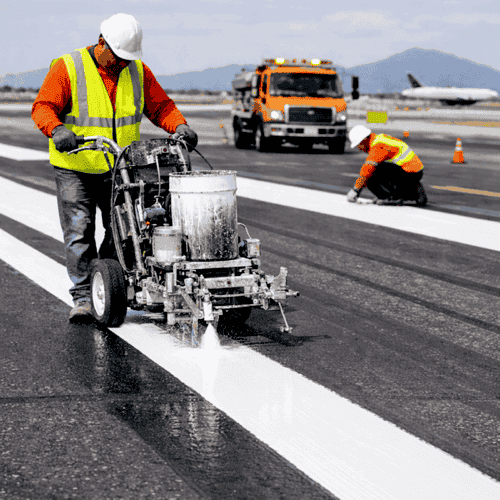

"Supplied oil kerb base paint for smart city road marking project. Our oil kerb paints provided excellent durability, high visibility, and weather resistance for urban infrastructure."

Oil Kerb Base Paint

High-performance oil kerb base paint manufacturers delivering durable, high-visibility curb and road marking paints for highways, urban roads, and infrastructure projects worldwide.

Product Performance Metrics

Real-time statistics showcasing our product excellence

| Parameter | Specification |

|---|---|

| Product Type | Oil Kerb Base Paint |

| Material Base | Synthetic Resin / Alkyd Oil Base |

| Application Method | Brush / Roller / Spray |

| Drying Time | Surface Dry – 30 Minutes |

| Finish | Smooth, Glossy & High Visibility |

| Colours Available | Black, Yellow, White & Custom |

| Adhesion | Excellent on Concrete & Asphalt |

| Compliance | IS164 -2023 |

Product Overview

YNM Safety is one of the leading oil kerb paint manufacturers in India, offering premium quality oil base paints designed for long-lasting curb and road edge markings. As trusted paints manufacturers, we deliver durable, weather-resistant, and high-visibility marking solutions for highways, urban roads, smart cities, and infrastructure projects. Our ynm safety oil paints manufacturers products ensure strong adhesion on concrete kerbs, medians, and dividers. The oil kerb base paint provides excellent colour retention, smooth finish, and resistance against dust, rain, and UV exposure. Being reputed oil paints manufacturers, YNM Safety focuses on consistent quality, fast drying performance, and compliance with industry standards for government and EPC projects.

Detailed Specifications

Complete product information including dimensions, origin, and manufacturing details

Export Availability

Our Oil Kerb Base Paint is available and exported to 20+ worldwide

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Product Specification

Key features and product advantages of our Oil Kerb Base Paint

Key Features & Benefits

Application Areas

Where our Oil Kerb Base Paint provides maximum road safety and protection

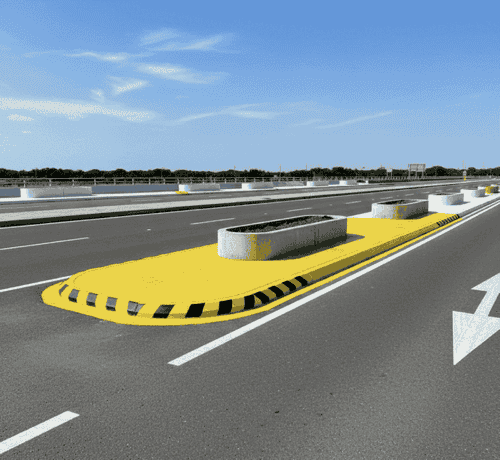

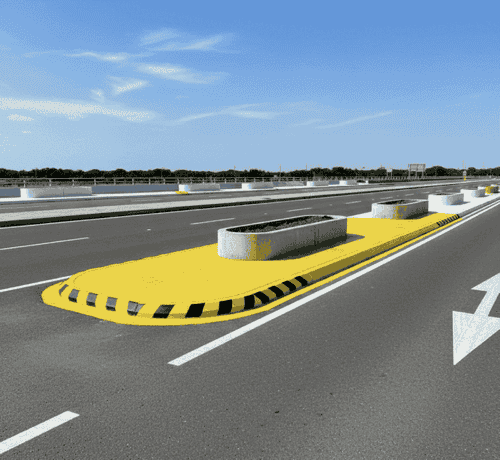

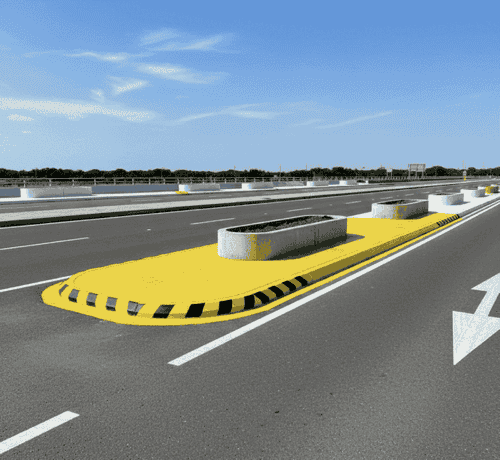

Traffic Islands & Medians

Oil kerb base paint provides high-visibility markings for traffic islands and medians, improving road guidance and safety.

Bus Stops & Terminals

Oil paints manufacturers supply durable kerb paints for bus stops and passenger terminals.

Kerbs and Road Edges

Oil kerb base paint is ideal for marking kerbs and road edges with sharp, durable finishes.

Curbs & Gutters

Oil kerb paint delivers clean and professional curb and gutter markings.

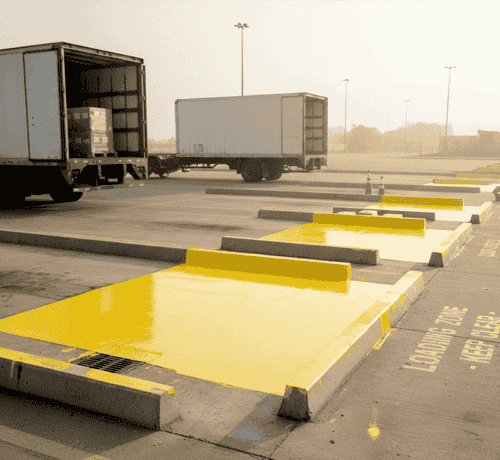

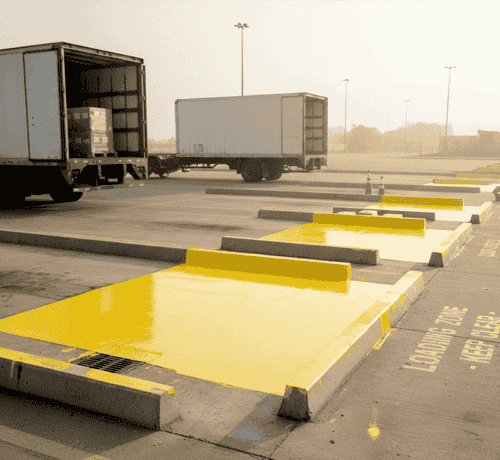

Loading / Unloading Zones

Oil kerb base paint ensures clear boundary markings in loading and unloading areas.

Safety Zones in Factories & Warehouses

Oil paints manufacturers provide high-contrast safety markings for factory and warehouse zones.

Market Growth

Oil Kerb Base Paint Market Growth | YNM Safety

The global market for oil-base kerb/base paint is witnessing steady growth due to increasing infrastructure development and stringent road safety regulations. It is projected to grow at a CAGR of around 4.3–4.8% over the next decade. Rising urbanization and expansion of road networks in emerging economies are key drivers. The market size is expected to increase significantly by 2030, reflecting growing demand for durable and high-visibility road markings.

Regional Market Share

Market Size Growth (in Billion USD)

Key Growth Factors of Oil Kerb Base Paint

Manufacturing Process of Oil Kerb Base Paint

As leading oil kerb paint manufacturers, YNM Safety follows a strict and quality-controlled manufacturing process to produce high-performance oil base kerb paint for highways, medians, road edges, and industrial safety zones. Being trusted oil paints manufacturers and professional paints manufacturers, every batch is produced under advanced supervision from raw materials to final dispatch.

Selection of Raw Materials

The manufacturing of oil base kerb paint begins with sourcing premium alkyd resin (oil-base binder), mineral turpentine oil (solvent), titanium dioxide and iron oxide pigments, fillers like calcium carbonate, and specialty additives such as driers and anti-settling agents. YNM Safety manufacturers only use approved and tested raw materials to ensure durability and long-lasting road marking performance.

Quality Inspection of Raw Materials

All raw materials undergo laboratory testing for viscosity, purity, moisture content, colour strength, and chemical stability. As responsible oil base kerb paint manufacturers, we ensure compliance with IRC and MORTH guidelines before releasing materials for production.

Resin Charging & Pre-Mixing

The alkyd oil resin is transferred into a high-speed disperser tank. Controlled quantities of mineral turpentine oil are added to adjust the base viscosity. This stage forms the foundation of high-performance oil kerb paint with proper flow and leveling properties.

Pigment & Extender Dispersion

Premium pigments and fillers are gradually added under continuous high-speed mixing. This dispersion process ensures uniform colour development, opacity, and brightness required for road kerbs, medians, and safety markings.

Grinding Process

The dispersed mixture is transferred to a bead mill or sand mill for fine grinding. Grinding reduces particle size to micron levels, giving smooth texture, strong adhesion, and superior finish — essential for long-lasting oil base kerb paint applications.

Let-Down & Additive Adjustment

After grinding, the base paste is returned to blending tanks. Additional resin, solvents, and performance additives such as drying agents and anti-skinning chemicals are incorporated. This step adjusts drying time, gloss level, durability, and weather resistance of the oil kerb base paint.

Filtration Process

The finished oil kerb paint is passed through fine filtration systems to remove impurities and ensure lump-free consistency. This guarantees smooth brush, roller, and spray application for highways and industrial zones.

Quality Control Testing

Each batch manufactured by ynm safety manufacturers undergoes strict quality checks including viscosity test, drying time analysis, adhesion testing, gloss measurement, opacity verification, and density & solid content testing. Only approved batches proceed to packaging.

Filling & Packaging

The approved oil base kerb paint is filled into durable 20 Kg MS containers using precision filling machines. Each container is labeled with batch number, manufacturing date, and compliance details — reinforcing YNM Safety's position among trusted oil paints manufacturers.

Storage & Dispatch

The finished products are stored in controlled warehouse conditions to maintain quality stability. Upon order confirmation, the oil kerb paint is palletized and dispatched safely to domestic and international clients, strengthening YNM Safety's reputation as reliable oil kerb paint manufacturers in India.

Factory & Quality Proof

See our manufacturing facility and quality certifications that ensure premium product quality

Our Manufacturing Facility

State-of-the-art production facility ensuring consistent quality

Coming Soon

Factory images and facility tour will be available shortly

Quality Standards

Compliance with national and international road safety standards

ISO 9001:2015

Quality Management System Certification

IS164 - 2023

Indian Standard for Road Marking Paint