Water Kerb Base Paint

High-performance water kerb base paint manufacturers delivering eco-friendly, durable, and high-visibility curb and road marking paints for highways, urban roads, and infrastructure projects worldwide.

Product Performance Metrics

Real-time statistics showcasing our product excellence

| Parameter | Specification |

|---|---|

| Product Type | Water Kerb Base Paint |

| Material Base | Acrylic Water Based Resin |

| Application Method | Brush / Roller / Spray |

| Drying Time | Surface Dry – 20–30 Minutes |

| Finish | Smooth, Matte / Semi-Gloss |

| Colours Available | Black, Yellow, White & Custom |

| Adhesion | Excellent on Concrete & Asphalt |

| Compliance | IS164:2023 |

Product Overview

YNM Safety is one of the leading water kerb paint manufacturers in India, offering premium-quality water base paints designed for long-lasting curb and road edge markings. As reliable water paints manufacturers and experienced paints manufacturers, we deliver eco-friendly, low-VOC, and high-visibility marking solutions for highways, smart cities, municipal roads, and infrastructure projects. Our ynm safety water base paints manufacturers products provide excellent adhesion on concrete kerbs, medians, and dividers while ensuring faster drying and environmental compliance. The water kerb base paint offers superior colour retention, crack resistance, and weather durability. Being reputed water paints manufacturers, YNM Safety focuses on sustainable production, consistent quality control, and compliance with IS 164 – 2023 standards for government and EPC projects.

Detailed Specifications

Complete product information including dimensions, origin, and manufacturing details

Export Availability

Our Water Kerb Base Paint is available and exported to 20+ worldwide

North America

Europe

Asia Pacific

Latin America

Product Specification

Key features and product advantages of our Water Kerb Base Paint

Key Features & Benefits

Application Areas

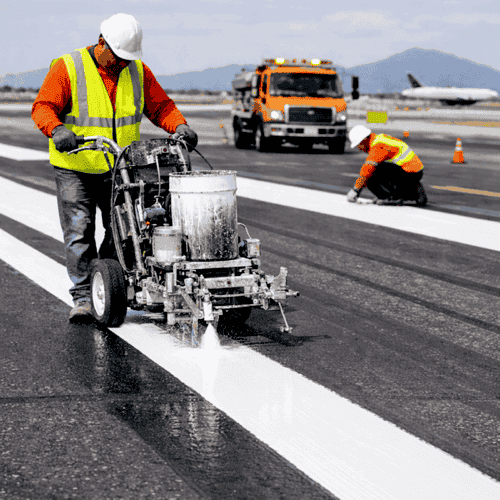

Where our Water Kerb Base Paint provides maximum road safety and protection

Kerbs and Road Edges

Water kerb base paint ensures sharp, high-visibility markings for kerbs and road edges.

Parking Lots

Water paints manufacturers supply durable markings for parking lot boundaries and curb sections.

Pedestrian Crossings

Water kerb base paint enhances pedestrian crossing visibility and road safety.

Road Markings

Water kerb paint is suitable for durable and eco-friendly road marking applications.

Industrial & Warehouse Floors

Water kerb base paint defines safety lines and boundaries in industrial facilities.

Public Spaces & Recreational Areas

Water paints manufacturers provide vibrant markings for public and recreational spaces.

Market Growth

Water-Based Road Marking Paint Market Growth | YNM Safety

The global water-based road marking paints market was valued at around USD 14.5 billion in 2024 and is projected to reach approximately USD 26.5 billion by 2032, growing at a CAGR of about 7.5% during the forecast period. Growth is also supported by rapid urbanization and the need for durable, high-visibility road markings in both developed and developing regions. Overall, the market outlook for water-based kerb/base paints remains strong and steadily rising through the early 2030s.

Regional Market Share

Market Size Growth (in Billion USD)

Key Growth Factors of Water Kerb Base Paint

Manufacturing Process of Water Kerb Base Paint

As leading water kerb paint manufacturers in India, YNM Safety follows a strict ISO 9001:2015 quality-controlled production system at our Hyderabad manufacturing facility. Our water kerb base paint is produced in compliance with IS 164:2023 standards to ensure durability, adhesion, and long-lasting road marking performance.

Procurement of Raw Materials

The process begins with sourcing premium acrylic water-based resin, titanium dioxide and iron oxide pigments, mineral fillers, performance additives (dispersants, defoamers, thickeners), preservatives, and treated water. As responsible ynm safety water base paints manufacturers, only approved and tested raw materials are accepted for production.

Raw Material Quality Inspection

All materials undergo laboratory testing for pH value, viscosity, solid content, colour strength, and chemical stability. This ensures compliance with IS 164:2023 standards and maintains consistency in every batch manufactured by YNM Safety.

Water & Additive Pre-Mixing

Measured quantities of processed water are charged into high-speed disperser tanks. Wetting agents, dispersing agents, and defoamers are added and mixed thoroughly to create a stable base solution. This stage improves pigment bonding and ensures uniform paint formulation.

Pigment & Filler Dispersion

Premium pigments and fillers are gradually added into the pre-mix under controlled high-speed agitation. This dispersion process ensures uniform colour development, brightness, and opacity required for kerbs, medians, road edges, and pedestrian markings.

Grinding Process

The mixture is transferred to a bead mill or sand mill for fine grinding. Grinding reduces particle size to micron levels, resulting in smooth texture, improved adhesion, and superior surface finish — essential for high-performance water kerb base paint.

Resin Let-Down & Final Blending

Acrylic water-based resin is added into the ground mixture in blending tanks. Performance additives are incorporated to enhance durability, drying time, weather resistance, and binding strength. This stage defines the final performance characteristics of the paint supplied by trusted water paints manufacturers.

Viscosity & Performance Adjustment

Thickeners and coalescing agents are added to achieve the required application viscosity and flow properties. As experienced paints manufacturers, YNM Safety ensures smooth brush, roller, and spray application.

Filtration

The finished water kerb base paint is passed through multi-stage filtration systems to remove impurities and ensure lump-free consistency. This guarantees professional finish during site application.

Quality Control Testing

Each batch manufactured by ynm safety manufacturers undergoes strict testing including: Viscosity test, pH test, Drying time analysis, Adhesion testing, Opacity & colour verification, and Density and solid content testing. Only batches meeting IS 164:2023 standards are approved for packaging.

Filling & Packaging

The approved water kerb paint is filled into 20L containers using automated filling machines. Each container is batch-coded, labeled with manufacturing details, and sealed securely. Minimum order quantity is maintained at 1 KL for bulk supply.

Storage & Dispatch

Finished goods are stored in a temperature-controlled warehouse to maintain product stability. Upon order confirmation, products are palletized and dispatched safely to domestic and international clients, strengthening YNM Safety's position among reliable water kerb paint manufacturers and exporters from India.

Factory & Quality Proof

See our manufacturing facility and quality certifications that ensure premium product quality

Our Manufacturing Facility

State-of-the-art production facility ensuring consistent quality

Coming Soon

Factory images and facility tour will be available shortly

Quality Standards

Compliance with national and international road safety standards

ISO 9001:2015

Quality Management System Certification

IS164:2023

Indian Standard for Road Marking Paint