Waterborne Airfield Marking Paints

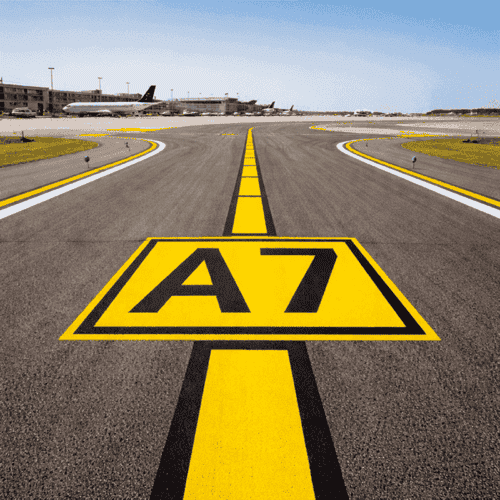

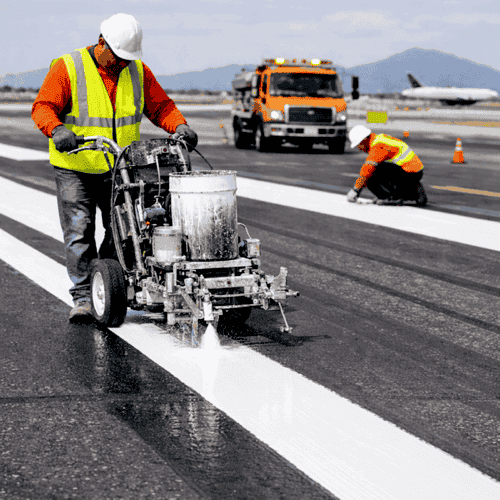

YNM Safety manufactures premium waterborne airfield marking paints engineered for superior visibility, fast drying, and long-lasting performance across airport and aviation infrastructure.

Product Performance Metrics

Real-time statistics showcasing our product excellence

| Parameter | Specification |

|---|---|

| Product Type | Waterborne Airfield Marking Paints |

| Base | Waterborne |

| Finish | Matt / Semi-Gloss |

| Drying Time | Fast Drying |

| Weather Resistance | Excellent |

| Adhesion | Strong adhesion on concrete & asphalt |

| Visibility | High contrast daytime & night visibility |

| Compliance | IS164- 2023 |

Product Overview

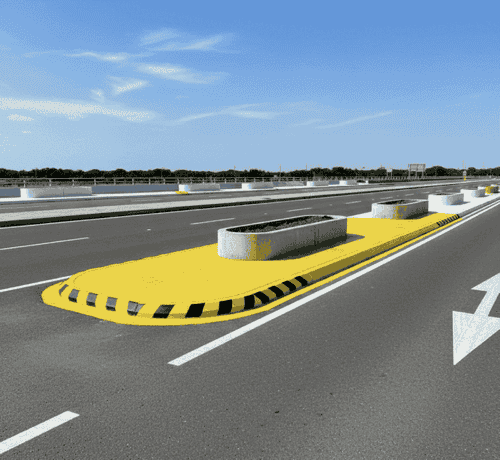

YNM Safety is a trusted name among waterborne airfield marking paints manufacturers, delivering high-performance airport marking solutions for modern aviation infrastructure. As leading YNM Safety manufacturers, our YNM Safety waterborne paints are specially formulated for runways, taxiways, aprons, and helipads, ensuring clear guidance, safety, and operational efficiency in critical airfield environments. Our YNM Safety Waterborne Airfield Marking Paints manufactured products offer excellent adhesion, fast curing, and long service life, making them ideal for high-traffic airport surfaces exposed to aircraft movement and harsh weather conditions.

Detailed Specifications

Complete product information including dimensions, origin, and manufacturing details

Export Availability

Our Waterborne Airfield Marking Paints is available and exported to 20+ worldwide

North America

Europe

Asia & Asia-Pacific

Latin America

Middle East & Africa

Product Specification

Key features and product advantages of our Waterborne Airfield Marking Paints

Key Features & Benefits

Application Areas

Where our Waterborne Airfield Marking Paints provides maximum road safety and protection

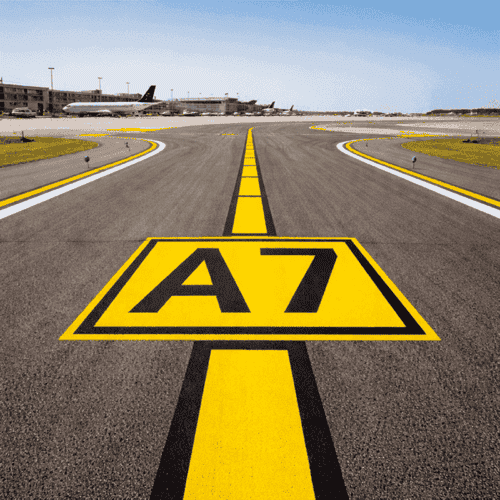

Runways

YNM Safety waterborne airfield marking paints deliver high-visibility runway markings for safe aircraft landing and take-off.

Taxiways

Waterborne airfield marking paints provide clear directional guidance on airport taxiways.

Aprons

Waterborne airfield marking paints support safe aircraft servicing and ground operations on aprons.

Aircraft Parking Bays

Clear aircraft parking bay markings ensure accurate positioning and safety.

Holding Position Markings

Holding position markings improve runway safety and aircraft control.

Helipads

Waterborne airfield marking paints provide durable and highly visible helipad markings.

Market Growth

Waterborne Airfield Marking Paint Market Growth

The water airfield marking paint market is growing steadily, driven by global airport expansion and stricter aviation safety standards. The market was valued at around USD 550–600 million in recent years and is projected to reach nearly USD 900 million–1 billion by the early 2030s. This reflects an average CAGR of about 5–6% over the forecast period. Growth is further supported by rising air traffic and the shift toward eco-friendly, low-VOC water-based coatings.

Regional Market Share

Market Size Growth (in Billion USD)

Key Growth Factors of Waterborne Airfield Marking Paints

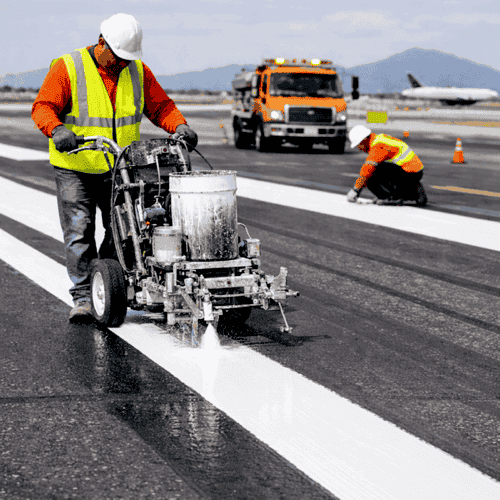

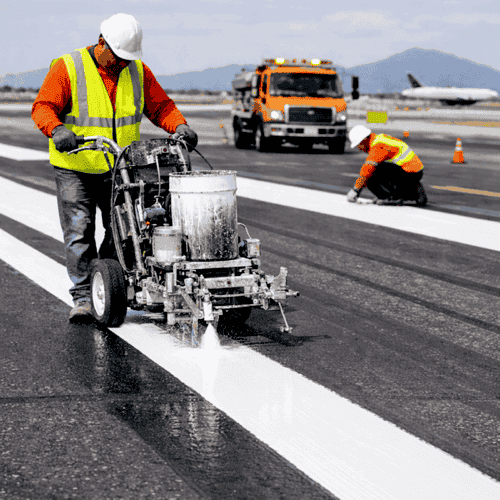

Manufacturing Process of Waterborne Airfield Marking Paints

YNM Safety manufactures Waterborne Airfield Marking Paints through a controlled, quality-driven process to ensure excellent visibility, adhesion, weather resistance, and compliance with aviation safety standards.

Raw Material Procurement

High-quality raw materials such as acrylic or styrene-acrylic emulsions, titanium dioxide pigments, extender fillers, additives, defoamers, and deionized water are sourced from approved suppliers to ensure consistency, durability, and compliance with airfield standards.

Raw Material Inspection & Quality Check

All incoming raw materials are tested for parameters like purity, viscosity, particle size, and moisture content to ensure they meet aviation and environmental specifications before production begins.

Pre-Mixing of Liquid Components

Water, binders, wetting agents, dispersants, and other liquid additives are charged into the mixing vessel and blended at controlled speed to create a uniform base mixture.

Pigment & Filler Dispersion

High-opacity pigments such as titanium dioxide and selected fillers are slowly added to the pre-mix. High-speed dispersers are used to achieve fine particle dispersion for excellent color brightness and visibility.

Grinding & Homogenization

The paint slurry is processed through grinding equipment to ensure uniform particle size, smooth texture, and consistent film performance required for runway and taxiway markings.

Let-Down & Final Mixing

Additional binders, performance additives, anti-settling agents, and rheology modifiers are added during the let-down stage to achieve the required viscosity, drying time, skid resistance, and durability.

Quality Control Testing

The finished paint is tested for color consistency, viscosity, drying time, adhesion, reflectivity compatibility, abrasion resistance, and compliance with ICAO / FAA / DGCA standards.

Filtration & Batch Approval

The paint is filtered to remove any impurities or agglomerates. After final inspection and approval by the quality team, the batch is released for packing.

Filling & Packaging

Approved paint is filled into HDPE drums or containers of required capacity, properly sealed, batch-coded, and labeled with product specifications and safety information.

Storage & Dispatch

Packed materials are stored in a controlled warehouse environment and dispatched as per customer orders with proper documentation to ensure safe transport and on-time delivery to airfield projects.

Factory & Quality Proof

See our manufacturing facility and quality certifications that ensure premium product quality

Our Manufacturing Facility

State-of-the-art production facility ensuring consistent quality

Coming Soon

Factory images and facility tour will be available shortly

Quality Standards

Compliance with national and international road safety standards

MoRTH 803

Ministry of Road Transport & Highways Section 803 Specifications

ISO 9001:2015

Quality Management System Certification

EN 1317

European Standard for Road Restraint Systems

IRC 119

Indian Roads Congress Guidelines for Traffic Safety Barriers